Miscellaneous Questions about Papercrete

Kelly Hart, who is your host at greenhomebuilding.com, has been involved with papercrete from the early days of its popularization. He included interviews with papercrete pioneers Mike McCain, Eric Patterson and Sean Sands in the video he produced: A Sampler of Alternative Homes: Approaching Sustainable Architecture. He also chronicled his own use of this amazing material in his video: Building with Bags: How We Made Our Experimental Earthbag/Papercrete House. Kelly has built and used both an electric barrel mixer, and a McCain-designed tow mixer. His house is plastered inside and out with papercrete and can be seen here. He can speak from his experience with this novel stuff, and is frank about both its pros and it cons.

Kelly Hart, who is your host at greenhomebuilding.com, has been involved with papercrete from the early days of its popularization. He included interviews with papercrete pioneers Mike McCain, Eric Patterson and Sean Sands in the video he produced: A Sampler of Alternative Homes: Approaching Sustainable Architecture. He also chronicled his own use of this amazing material in his video: Building with Bags: How We Made Our Experimental Earthbag/Papercrete House. Kelly has built and used both an electric barrel mixer, and a McCain-designed tow mixer. His house is plastered inside and out with papercrete and can be seen here. He can speak from his experience with this novel stuff, and is frank about both its pros and it cons.

Questions and Answers

C: (Vince Pawlowski) I was just reading your article in the Art of Natural Building, as part of the historical research that lead to the recent papercrete conference. It seems that nobody really knows the time sequence of many early contributors like Bill Knauss. Mike McCain in a personal visit (represented at the conference by partner, Peter Edmunds) and Eric Patterson both put forth their versions of papercrete history, but there is much still missing, most notably the mysterious "James Moon", who had a company named Harmony Domes in the early 1980's. The major news is about MasonGreenstar.com. They claim they will have a commercial papercrete product ready in a year or so.

R: As to the history of papercrete, it does seem to be shrouded in some mystery. I first heard about it from an article in a New Mexico paper about Eric Patterson's patent and a description of his "padobe." Then I met Mike McCain in Crestone, CO (where I was living) and he seemed to think that he had invented it. I interviewed both of them for my video program, "A Sampler of Alternative Homes." I actually think that they both did invent it independently of each other.

But then quite awhile later I heard about Bill Knauss, who claimed to have made a small building with it some time before either of them. I have never substantiated this, nor met him. An now this James Moon, who I have never heard of. Also, there is Mr. Paul A. McKelvey from Redlands, California. He also has a patent on papercrete, issued after Eric's! See http://www.greenhomebuilding.com/weblog/2006/12/papercrete-patents.htm I don't know anything about the 1928 patent that the reader comments on in that blog...It is interesting about the Mason Greenstar Company...he says that they now have a patent! And so the world turns.

Q: I have read all your articles on papercrete and find them very interesting. I have made my own papercrete blocks and have had them tested for strength. I wish to make blocks to resell but unfortunately I have been told that there is a patent on the papercrete blocks and that I would have to pay royalties to be able to sell them. The person that has the patent is Mr. Paul A. McKelvey from Redlands, California. I don't see how he could have a patent on papercrete since it's been patented once, in 1928, and so many people have been using it since then. I would really like to know your thoughts on this subject.

A: You are right that Mr. McKelvey should never have been issued a patent for that process, since it had already been patented. His patent is #5,785,419, issued on 7/28/98, and it was for a "lightweight building material and method of construction of cast-in-place structures" and the material comprises "cement, fly ash, cellulose fiber, and water."

Prior to his patent is #5,350,451, which was issued to Eric Patterson in Silver City, New Mexico (issued 9/27/94) for essentially the same material and process:

" A slurry composed of paper fibers, water, and cement that can then be used for a variety of construction applications is prepared. After draining the majority of the water, the slurry may be molded into blocks, sheets, or any other desired shape to be used as a construction material, or it can be sprayed onto wire shapes to form custom structures. The slurry product can be used as a mortar in conjunction with building blocks that have been made from the slurry, and it can be used as a plaster when mixed with conventional cement and sand mortar. The slurry can also be poured into forms in the same manner as concrete to form blocks for construction applications."

The only material difference between the two patents is the addition of fly ash to the later patent, and that is a common additive to Portland cement and should have not been allowed as a significant difference.

In any case, I just talked to Eric Patterson by phone and he says that he is not enforcing the control of his patent and is offering his process and material for the general public to be used in any way they deem appropriate, without any expectation of remuneration or contracted commissions. So he suggests that you proceed with your project, and use his patent as the one under which you are operating. If you do not include fly ash in your formula, then Mr. McKelvey would have no recourse for making claims against you.

Q: I wish to make some papercrete structures for horse and chickens. My horses eat wood at every opportunity. It would be nice if they had a home they would not eat! I also think that it could be feasible to destroy the chickens coup and build a new one each spring.

A: I doubt that horses or chickens would find papercrete very palatable; I know that insects do not like it. However, I also know that the reason why horses will "crib" on the wood around them is often because they are bored and feel confined. In this case, they could certainly nibble at the papercrete as well as wood, perhaps even easier. The same is true of chickens.

Q: I am searching for a different technique to "cast" from figures made in oil-based clay and then creating a rubber mold with a plaster mother mold. The material to be packed into or poured into the mold is what I am interested in investigating. I want a look of natural stone, without having to spend all the time to carve from natural stone. Would papercrete do this?

A: Papercrete doesn't really resemble stone much, since it tends to be much softer and gray cement color. It can, of course be painted, or pigment added to the wet mix to change the appearance. Also lots of sand and/or clay can be added to make it harder and change the color some as well. You could experiment with a small amount, by mixing it up in a blender. Soak some newspaper for awhile in water, then run some of this through your blender, until it becomes a soupy slurry. Add maybe a cup of portland cement and some sand to this and then allow the slurry to drain in a colander until it become clay-like. It takes quite a while to cure, and doesn't tend to set up as quickly as concrete. In fact if it isn't allowed to dry out it won't properly cure. It will set up to some extent while green, perhaps enough to release from your mold so that it can cure the rest of the way.

Q: We are getting ready to start a "superadobe" home possibly covered with papercrete. But I need to find out if the papercrete would be potable for catching rainwater for a cistern? And also, if plastic is used as a vapor barrier or for waterproofing how does the papercrete adhere?

A: Papercrete would not be ideal for water catchment, mainly because it tends to absorb most of the moisture that hits it, and then allows it to evaporate later. Also, there could be some toxic residue from the paper, ink or cement that might not be healthful. Papercrete does not adhere to plastic. I have used chicken wire mesh over plastic to form a stable plaster.

C: I know of a cordwood barn with papercrete mortar. I believe the mortar was about 20% portland cement and 80% paper. It's been standing for about 12 years now and still looks good as new except for a few logs loosening up. In the construction of our cordwood house I am using recycled newspaper in the mortar. About 40% of the mortar is slurried newspaper. Although it is not "traditional" papercrete, it's pretty close. I've coined an acronym for it: PEM (Paper Enhanced Mortar). It is experimental in nature, but I feel confident enough to build our house with it.

Q: I have severe environmental allergies. It is almost impossible for me to live in a home that requires open windows for cooling the air. Do you know of any reason that an energy efficient HVAC unit would not work in a papercrete house?

A: No. I see no reason why such a system would not work in a papercrete house.

Q: I am an Interior Designer and looking for all natural materials to fit out a new club here in Seattle. I wanted to make one vertical 24' wide by 4' high wall under the bar and two vertical flat surfaces 2' wide by 6' tall to look like concrete blocks. Can papercrete be used to get this effect? and or any other suggestions for me. We are in a hurry to open by the end of the month and need it to be a durable, unique surface that the health dept will approve.

A: I don't think that papercrete is your answer. Although you could make it look like concrete blocks, it would take a lot of work, and a very long to time to cure (longer than the end of this month), and I doubt that the health department would be very pleased with it. My suggestion is to use concrete blocks, if that is the look that you want, and seal them with something, if that is an issue for the health department.

Q: Is straw an alternative to paper in papercrete? I was considering creating a slurry and as i poured it into molds, I would also apply straw and then mix it up in my forms to build panels out of. What is your take on this?

A: It is possible to add straw to cement to help keep it from cracking, or to add straw to papercrete for the same reason, but you would still need the paper pulp in there to make it all stick together as a solid material.

Q: I want to create an outdoor sculpture that both withstands New England frosts of -20 and retains water to accept plants to grow on it, like grasses, mosses and creepers. I guess I need a medium that is highly sculptural and retains moisture and at the same time withstands intense cold. Any ideas?

A: One idea that comes to mind is to use papercrete for this; it is a very sculptural material that I know from experience can withstand the temperatures that you mention, and it hold moisture like a sponge.

Q: How does a papercrete home do in heavy winds and heavy sandblasting on the desert terrain?

A: If the home is designed well, it can withstand wind loads for sure, and it seems to be fairly durable as well, depending on the mix.

Q: How long would you suspect that a papercrete home last?

A: This is hard to say, since we don't have enough experience with the material. One fellow who built a PC shed about 20 years ago claims that it is as good as new.

Q: I live in Serbia & Montenegro (former Yugoslavia). My wife and I decided to build a small papercrete house, about 40 square meters. The only info we have is from the Internet. We thought about purchasing a book, but we don't know which one. The standards are pretty different here than in the USA. If I say that the house will cost us 2.000 EUR, and that this is a bit over our budget, you can understand we don't have the money to buy several books and choose the one we like best. And on the other hand I feel that there is so much yet to be discovered about papercrete, that the only way is to try it yourself. However, as this will be our house, not just a shed, we need some expert opinion before we start.

A: There is actually rather limited information available about papercrete, partly because it has not been used for very long. The one actual book is really just a compilation of articles written by early experimenters. While valuable, this information is certainly not definitive. Likewise, the video and DVD that are listed at on this page provide some information, but leave much to be learned. Your decision to try it yourselves is probably a good one, given this reality. On the other hand, it would be best for you to learn from the mistakes that others have made, so that you don't have to repeat them. The information that I have assembled, especially on the pages listing questions and answers can help guide you to some extent. The more information you have at hand the better. It is possible to make some disastrous mistakes, and I have known some who have. Most of my cautions are fully expressed at my website. I don't mind occasionally answering a question or two, but I can't be responsible for guiding you through your entire project.

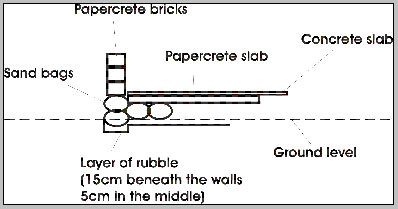

Q: By no means do we expect you to guide us through our project. But we don't want to make any irreversible mistakes. That's why our main concern is the foundations. I attached an image which shows what we intend to do. Do you think this (the rubble and sandbags) will be enough to keep the water from wicking up into the papercrete? And one other thing. On living paper.com I read about vertical and horizontal rebar reinforcements in the walls. Are they necessary?

A: As a precaution, I would advise you to fill the earthbags that underlay the floor and walls with a loose gravel, which will keep any water intrusion from wicking up. 5 cm of rubble is not much of a barrier to wicking. You could probably get by without the bags under the floor, and just increase the depth of the rubble, or gravel in that area. Otherwise, your scheme looks pretty good. As for reinforcing the walls, I would say it depends on how much you want to protect the structure against possible earthquakes. As with concrete, the steel reinforcement would help keep the wall from breaking apart under seismic strain.

Q: We are planning on dry stacking the block on our house in Baja, Mexico. It is very warm here year round. None of this will be below grade. We are concerned that we won't be able to find the Calcium Stearate and Calcium Chloride. Can we make the surface bonding mix using only cement, lime, and fiberglass?? Can we substitute with some kind of plastic cement?

A: Surface bonding relies on very good bonding of the materials to be effective. It seems possible to me that some mixture of cement with glass fibers and maybe something else to improve the adhesion would work. One idea might be to try mixing in some latex (known as "resina" in Mexico). This definitely calls for some careful experiments on small areas to see what works.

Q: I am trying to get a papercrete project going here in the Virgin Islands and have a question I can't seem to find an answer to. Can salt [seawater] be used for making papercrete? Would I have to dilute it? This would save me lots of money. Also, do you think it would be a good material to use as filler for a tire structure?

A: The question about the use of seawater to make papercrete is one I don't have a definitive answer for. The critical factor might be whether portland cement will cure when mixed with saltwater rather than fresh water. You might ask around about this, because I don't know the answer. If it were me, I would do some experimenting and see what happens. The use of papercrete for building is so new that there is much to be learned about how useful this material will be over time.

As for filling tires with papercrete, I would not advise it because papercrete is very wet when fresh and must drain and evaporate a lot of moisture before it becomes dry and cured. In a tire this may never happen. Also, even the cured material is not dense enough to have sufficient compressive strength for filling tires. Ordinary earth is much better for this application.

Q: As a first-year student in a French School of Engineering ("Ecole Centrale de Nantes"), I work on the study of environment-friendly building materials and more especially on the papercrete. I have seen that the papercrete is fireproof, but I would like to know the classification (M0,M1...)?

A: I would not say that papercrete is fireproof; it will burn (smolder, actually) if sufficiently ignited, and it can sustain such a smolder until the material has turned to nothing but ash! The degree to which papercrete will burn depends on how much mineral or earthen material and cement is added to it...the more minerals the less burnable.

Q: We are wondering about bringing papercrete technology as an affordable building technique to communities in Mexico. Do you know any communities where you are that might benefit?

A: In the US you can build a house by utilizing junk mail, but in Mexico most people don't get mail delivered, nor do they subscribe to newspapers and collect lots of paper. In other words, one would have to find a good source for junk paper to make papercrete. This fact, coupled with the need to fabricate some kind of mixer, makes the proposition of this catching on in Mexico somewhat limited. I think that the greatest likelihood is that somebody would realize that a business opportunity exists in manufacturing papercrete blocks for sale. But then these would have to compete with the standard concrete blocks that are available for about 20 cents apiece and everybody is used to. Papercrete would have the tremendous advantage of being an insulating material...but this fact is not generally known, so people would have to be educated. So, while I would say that introducing papercrete successfully in Mexico is possible, there are challenges to doing so.

Q:

How does papercrete affect the overall health of an individual living in such an environment?

A: A well-built papercrete home can be both comfortable, economical and energy-efficient over time. But I must emphasis the "well-built" aspect of this statement because papercrete has a potential for adverse health effects. In particular, papercrete must be kept dry most of the time, because it is an ideal substance for molds to inhabit. And papercrete will wick and hold moisture like a sponge, so once it gets wet it will stay wet for awhile. To avoid potential risks, it is best to leave papercrete completely breathable, as attempts to exclude the entry of moisture with barriers such as paint or other membranes can make the problem worse. Papercrete is like strawbales in this regard, and the building needs a good foundation, well off the ground, and a roof with a substantial eave to keep it as dry as possible.

Q: I am a mosaic artist in Denver and I have been trying to use only recycled materials in my work (broken dishes... etc) I am trying to find a way to use papercrete as my substrate for building outdoor mosaics. Is there a formula/method or book I can use that would be appropriate for smaller art projects (as opposed to house-size projects?)

A: I am not sure that papercrete would be a good substrate for this. Unless the mosaic project is completely protected from the weather, there is considerable danger that moisture will find its way into the papercrete, which will absorb it like a sponge, and pretty soon you have a soggy mess of an interior that may not hold the the mosaic pieces any more. Better to use something more solid if this happens, like lightweight concrete. See this page for more information about this.

Q: Has anybody work with making siding for an existing house out of papercrete? What would the be the best way to strengthen the papercrete so one could handle it? Would placing Tyvek behind the PC solve the moisture wicking problem? Would the PC hold up over time in North Carolina area?

A: I can't say that I would recommend using papercrete as siding. It would take a lot of reinforcing wire mesh to make it hold together in thin applications, and it wouldn't hold up to the elements over time as well as many other materials.

Q: I read somewhere that papercrete was actually patented in the 1920s but can't find anything more about its origins. Do you know?

A: I have never been able to track down that supposed patent. It was definitely patented by Eric Patterson in the 90's, so I have my doubts about that prior patent...or it was a very different substance. Eric has no intention of using his patent to keep others from experimenting (or commercializing) with papercrete.

Q: I'm thinking about building a papercrete building. I would like to make all of it out of papercrete, even the floor. Can you tell me if I add extra cement in the mixture will this make my slab hard enough to walk on? Or if I covered it in ferrocement would this work. If I can make it out of papercrete it will have a vapor barrier in place to protect it from the ground moisture. Do you know of any other alternative methods I can use for the slab that is cheap? The building will be a 14x 80. And 15 yards of concrete for this is a $1600.00 + So any help would be greatly appreciated. Also if you add more sand to papercrete does that make it harder or more durable.

A: I would not normally advise someone to make a floor out of papercrete, since it is inherently less durable than other traditional flooring materials. I did once use papercrete in a building's entrance, but in this instance I had set flagstone down into it, so that the PC was accessible only as grout on the surface. This did work OK, but it was not really subject to much wear. If you do this, a moisture barrier between it and the soil beneath would be essential; maybe even pouring it over a bed of gravel to stop any wicking would be good. And yes, the more sand or mineral material you add to the PC, the more durable it would be. Putting a layer of ferrocement over the PC is another possibility that might work to decrease the cost. Another inexpensive option would be an adobe floor, but this takes some expertise to install and must be maintained over time. Like PC it is subject to some abrasion.

Q: I am located in the foothills of North Carolina. Currently I am experiencing long drying times with my papercrete due to the high humidity here. How can I speed up drying time while maintaining structural performance of the papercrete? I am using: 2 spades full of Portland cement, 6 spades full of sand, approximately 10 gallons of paper that has been blended in a blender then the water strained off until it is just mush. This yields one wheel barrel load of papercrete for me.

A: The only thing that comes to mind is to increase the temperature of where the drying needs to occur, or the use of fans to keep the air moving more, or both. This could be done perhaps with a solar effect using plastic or glass to trap the heat and a fan to move it away from the area. I don't think that this would adversely affect the structural performance of the PC.

Q: I don't quite understand why this is not an approved building material. Is it because the "mixture" hasn't been standardized? With the right "recipe" how come it can't be commercialized? I live in Brazil, and I look at the building process here and I don't see why it can't be substituted for the brick/cement construction they currently use. Plus if the R value is as good I've read, it seems like a no brainer. I'm going to start by constructing an addition on my home, but I think their is a market for this product here.

A: I don't know what the criteria are in Brazil for "approved" building materials. Here in the US most common building materials have been standardized through engineered tests and then accepted by the agencies that provide codes for building. All of this takes time and money, so newly introduced materials are at a disadvantage. Sometimes it is possible to substitute alternative materials (or building techniques) for those that have been proven reliable if an engineer is willing to vouch for their usefulness or safety, or if the inspector deems them equivalent to accepted practice. Papercrete hasn't been around long enough to have been run through this mill, or at least people generally haven't found it economically feasible to produce commercial products based on it.

Q: I'm studying Industrial Engineering. For my master's thesis I'm doing a development aid project in Benin (Africa). The project is about optimizing ovens for smoking fish, with the goal to improve the labour conditions. For a part of my master's thesis I'm doing some research about the use of papercrete blocks to build these ovens. Do you have any experience with building ovens from papercrete?

A: I would caution you to not use papercrete blocks in association with an oven, or if you do use them, keep them far away from any heated surface. Papercrete will burn, and can actually smolder without detection for quite some time, and then just disintegrate. The real value of papercrete is as an insulating material, not as a refractory material. I'm not sure exactly what temperature is needed to ignite papercrete, but this is influenced by how much mineral material might be added to it; the more sand, etc. is added, the most fire resistant it is...but of course this also makes it less insulating.

Q: We're thinking of building with papercrete in Alaska. Are you comfortable with this in cold/humid climates?

A: Papercrete takes several weeks to dry out in the best of circumstances: warm, dry air. I expect that that is possible during the long summer days in Alaska when the sun hardly sets. Papercrete can certainly handle some humidity, just like strawbales can, as long as it is allowed to breath. The fact that much of the time the climate is so cold would help the situation because mold needs warm conditions to flourish, and cold air holds much less moisture than warmer air. My guess is that a papercrete house with well protected walls that were finished well before the onset of frosts would probably survive. Timing would be critical, and for this reason alone, papercrete may not be the best choice in that climate. Once it were cured and kept relatively dry I would think that the papercrete could handle the freezing temperatures just fine. It is amazingly stable dimensionally and quite unaffected by freeze-thaw cycles.

Q: Someone replying to my question in a YouTube comment suggested you had experience in covering a frameless metal arch building with Papercrete. I just erected a 25x32 singlehandedly. Can you offer any advise from your experience?

A: Yes, I did use papercrete as a plaster over a metal arch building, but between the plaster and the metal were stacked earthbags filled with crushed volcanic stone. You can see pictures and read more about this project at earthbagbuilding.com. I'm not sure how well this approach would work without the earthbags. Papercrete holds moisture like a sponge and when it is wet it doesn't provide very good insulation. This is where the earthbags and lightweight stone provided the insulation and the papercrete just protected the bags. Also this was done in a rather arid environment.

Q: I would like to do poured in place countertops, and I am wondering, with discussion around wicking, if papercrete can be used as counters in the kitchen.

A: Papercrete would not be a good choice for a counter top; it is way too soft and spongy. Concrete is much more commonly poured for counter tops.