Shotcrete Systems

Shotcrete is sprayed concrete. There are both wet and dry methods of doing this. The aggregate must be quite fine, more like mortar to be able to do this, and usually the percentage of Portland cement to sand is quite high to create a very strong product. A distinct advantage of systems that employ shotcrete is that the concrete shell of the building can be exposed to the inside, where it's thermal mass can be fully utilized. Usually some form of steel mesh is provided to give tensile strength to the wall, which is then insulated in various ways from the atmosphere.

Informative Links & Books

The books shown below are arranged according to when they were published, with the most recent ones at the top. If you click on one of the images you will be taken to a page at Amazon.com where you can find out more about the book. If you end up buying one of them, greenhomebuilding.com will receive a small commission that will help cover the cost of maintaining this website. Thanks for your patronage.

Monolithic Domes

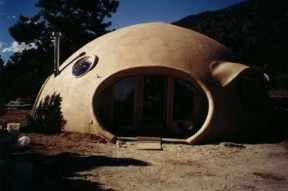

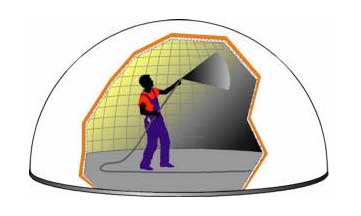

One of the more imaginative systems for using shotcrete is Monolithic Domes' approach. They have pioneered the use of an inflated balloon-like structure which acts as a form for the eventual building. They actually have two different ways of doing this: one retains the fabric of the form as a part of the exterior of the building, and the other allows the form to be reused several times for other buildings. In the first instance, polyurethane foam insulation is spayed on the inside of the form and then allowed to set up. Then rebar is assembled beneath this to conform with the shape established, and the shotcrete to sprayed onto the steel reinforcing from the inside. Once this has set up, the resulting building is about as tough as anything made by man. Domes of this sort have withstood hurricanes and earthquakes; even cannonshot would not knock one of these down!

One of the more imaginative systems for using shotcrete is Monolithic Domes' approach. They have pioneered the use of an inflated balloon-like structure which acts as a form for the eventual building. They actually have two different ways of doing this: one retains the fabric of the form as a part of the exterior of the building, and the other allows the form to be reused several times for other buildings. In the first instance, polyurethane foam insulation is spayed on the inside of the form and then allowed to set up. Then rebar is assembled beneath this to conform with the shape established, and the shotcrete to sprayed onto the steel reinforcing from the inside. Once this has set up, the resulting building is about as tough as anything made by man. Domes of this sort have withstood hurricanes and earthquakes; even cannonshot would not knock one of these down!

The second of Monolthic's methods of building uses a similar inflated balloon, but the rebar is tied outside of it and the shotcrete is applied from the outside. Once this has set up, the fabric can be deflated and removed for reuse. In this case the polyurethane insulation would also be sprayed on from the outside, with some sort of protective covering for durability.

I have witnessed several of these domes being constructed, and I would have to say that the process of building this way is really very high-tech; it relies on a great deal of machinery working optimally, and is not particularly pleasant to be around. While the building process goes fairly quickly, it is not for the faint of heart. There is the blower that keeps the balloon inflated, the urethane foam spraying equipment, the compressor to run the shotcrete machine, the cement mixer and equipment to keep it fed with materials, lights to be able to see what is going on, masks to keep from breathing all of the fumes and particulates in the air, etc. This requires a well organized crew of workers who are trained in their special tasks.

I have witnessed several of these domes being constructed, and I would have to say that the process of building this way is really very high-tech; it relies on a great deal of machinery working optimally, and is not particularly pleasant to be around. While the building process goes fairly quickly, it is not for the faint of heart. There is the blower that keeps the balloon inflated, the urethane foam spraying equipment, the compressor to run the shotcrete machine, the cement mixer and equipment to keep it fed with materials, lights to be able to see what is going on, masks to keep from breathing all of the fumes and particulates in the air, etc. This requires a well organized crew of workers who are trained in their special tasks.

Here is the main website for Monolithic Domes: monolithic.com. The above images are courtesy of Monolithic Domes.

Ferrocement

Ferrocement has been described as "a thin composite made with a cement-based mortar matrix reinforced with closely spaced layers of small diameter wire mesh." Ferrocement was first discovered in 1848 in France by Joseph Lambot and patented by him in 1852. This predates reinforced concrete by 25-30 years.

Simply put, reinforced concrete, including shotcrete, contains cement, sand and an aggregate of stone, along with reinforcing steel usually in the form of rebar and sometimes heavy duty wire mesh, i.e. 6x6x6x6 or 6x6x10x10. The aggregate in concrete can be as small as 1/4" and gets larger from there depending on mix design and application. Ferrocement never uses aggregate but is composed of sand, Portland cement and wire mesh.

There is a method called laminated Ferrocement that was patented by Martin Iorns in the 1960's. In this method mortar [sand and cement] are sprayed into a negative cavity mold and a layer of mesh is imbedded into the mortar. The sequence is repeated until the desired number of layers are completed.

greenbuildingforum.co.uk This forum has a lengthy discussion about "ASMET," an obvious variation of the basic concept of ferrocement, but with many worthwhile considerations expressed.

Performance Building Sytems

earthshelter.com kit for underground shotcrete dome houses.

earthshelter.com kit for underground shotcrete dome houses.

formworksbuilding.com shows interior and exterior images of several of their underground or bermed ferrocement buildings.

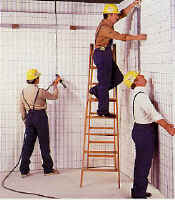

Shotcrete Sandwich Panels

For more conventional vertical wall buildings, there are several manufacturers of shotcrete sandwich panel systems. These systems employ an EPS core for insulation, with wire mesh attached to both sides of it. Once the panels are erected on site, the shotcrete is applied to both sides. Depending on how thick the EPS insulation is, the potential R-values can be quite high.

For more conventional vertical wall buildings, there are several manufacturers of shotcrete sandwich panel systems. These systems employ an EPS core for insulation, with wire mesh attached to both sides of it. Once the panels are erected on site, the shotcrete is applied to both sides. Depending on how thick the EPS insulation is, the potential R-values can be quite high.

Here are some links to manufacturers of these systems:

solarcrete.com

tridipanel.com

Form Free Buildiing

For Email contact go to About Us

Established in 2001, GreenHomeBuilding.com is primarily a labor of love. Kelly, and the GreenHomeBuilding team of experts, have answered thousands of questions for readers over the years, and we continue to publish up-to-date information about increasingly important sustainable architecture. If you feel moved to assist us in this work, your kind donation would be much appreciated; this can be easily done through our PayPal account:

VISIT OUR OTHER WEBSITES:

[Natural Building Blog] [Earthbag Building] [Dream Green Homes]

Disclaimer Of Liability And Warranty

I specifically disclaim any warranty, either expressed or implied, concerning the information on these pages. Neither I nor any of the advisor/consultants associated with this site will have liability for loss, damage, or injury, resulting from the use of any information found on this, or any other page at this site. Kelly Hart, Hartworks LLC.